Are you looking to optimize the efficiency of your production line? Choosing the right conveyor belt types plays a crucial role in achieving this goal. With the right conveyor belt, your operations can run smoothly and efficiently, minimizing downtime and maximizing productivity.When selecting a conveyor belt type, several factors need to be considered. The material being transported, the speed and capacity required, and the environmental conditions all play a role in determining the most suitable option.For example, if you need to transport heavy and abrasive materials, a durable and resistant conveyor belt made of sturdy materials like rubber or steel might be necessary. On the other hand, if you’re dealing with delicate or fragile items, a belt with a gentle grip and lower friction might be more appropriate.By selecting the right conveyor belt type, you can ensure minimal wear and tear, reduced maintenance costs, and increased efficiency for your production line. Don’t overlook the importance of this crucial component in your operations. Choose wisely and reap the benefits of improved efficiency and productivity.

Understanding the importance of selecting the right conveyor belt type

In any production line, the conveyor belt is the backbone that keeps things moving. It is responsible for the transportation of materials from one point to another, ensuring a continuous flow of production. However, not all conveyor belts are created equal, and selecting the right type is crucial for optimizing efficiency.One of the main reasons why selecting the right conveyor belt type is important is because different materials require different handling. For instance, if you’re working with heavy and abrasive materials such as sand or gravel, a conveyor belt made of robust materials like rubber or steel can withstand the wear and tear caused by the weight and friction. On the other hand, if you’re transporting delicate or fragile items, a belt with a gentle grip and lower friction is necessary to prevent damage.The conveyor belt type also plays a significant role in determining the speed and capacity of your production line. A belt that is too slow or has a low load capacity can lead to bottlenecks and reduced productivity. On the other hand, a belt that is too fast or has a high load capacity might put excessive strain on the system, leading to breakdowns and increased maintenance costs. Hence, it is crucial to understand the specific requirements of your industry and choose a conveyor belt type that aligns with those needs.

Factors to consider when choosing a conveyor belt type

When selecting a conveyor belt type, there are several factors that need to be taken into consideration. These factors will help determine the most suitable option for your specific needs.

1. Material Compatibility: The type of material being transported is a critical factor in selecting the right conveyor belt. Different materials have different characteristics and require different handling. For example, food-grade belts are designed to meet strict hygiene standards and prevent contamination, while belts for heavy-duty applications need to be durable and resistant to wear and tear.

2. Environmental Conditions: The environment in which the conveyor belt will operate is another significant consideration. Factors such as temperature, humidity, and exposure to chemicals or corrosive substances can impact the performance and lifespan of the belt. It is crucial to choose a conveyor belt type that can withstand the specific environmental conditions of your facility.

3. Speed and Capacity: The required speed and capacity of the conveyor belt will depend on the production demands of your facility. It is important to choose a belt that can handle the desired throughput without compromising efficiency or causing bottlenecks. Additionally, considering future growth and scalability is essential to avoid the need for frequent belt replacements.

Different types of conveyor belts and their applications

There are various types of conveyor belts available, each designed for specific applications and industries. Understanding the different types can help you make an informed decision when selecting the most suitable option for your production line. Let’s explore some of the common types of conveyor belts and their applications.

1. Flat Belt Conveyors: Flat belt conveyors are the most common type of conveyor belt, known for their versatility and wide range of applications. They consist of a flat, continuous loop of fabric or rubber that moves materials from one end to another. Flat belt conveyors are suitable for transporting a wide variety of materials, including small parts, loose goods, and bulk materials.

2. Modular Belt Conveyors: Modular belt conveyors are made up of individual plastic or metal modules that are linked together to form a continuous belt. These belts are highly customizable and can be tailored to specific applications. Modular belt conveyors are commonly used in industries such as food processing, packaging, and automotive, where hygiene, flexibility, and durability are crucial.

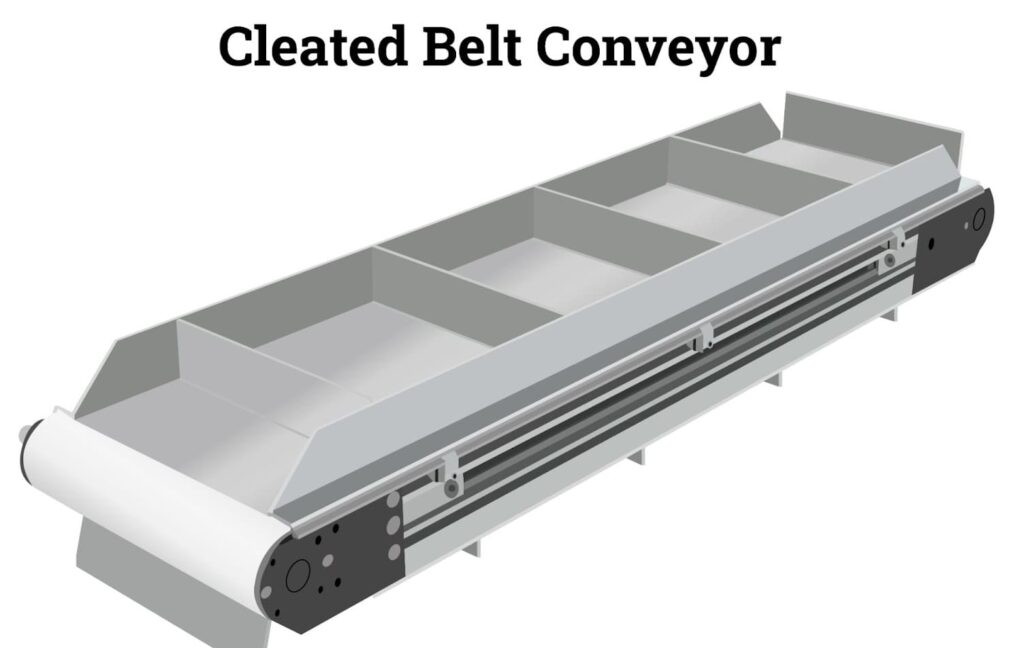

3. Cleated Belt Conveyors: Cleated belt conveyors have vertical or angled cleats on the belt’s surface that help prevent materials from sliding or falling off. These conveyors are commonly used in applications where inclined or steep conveying is required, such as in agriculture, mining, or construction. The cleats provide additional grip and stability, allowing for efficient transportation of bulk materials or items with irregular shapes.

4. Wire Mesh Conveyors: Wire mesh conveyors are made of interlinked metal wire mesh belts that allow for excellent air and liquid flow. These belts are commonly used in industries such as baking, drying, or cooling, where proper air circulation is crucial. Wire mesh conveyors are also suitable for high-temperature applications or environments where cleanliness is essential.

Assessing the specific needs of your industry

Every industry has unique requirements and challenges when it comes to conveyor belt selection. Assessing the specific needs of your industry is crucial for choosing the right conveyor belt type that can optimize efficiency and productivity. Here are some industry-specific considerations to keep in mind:

1. Food and Beverage: In the food and beverage industry, hygiene and safety are of utmost importance. Conveyor belts for this industry need to be food-grade and comply with strict regulations to prevent contamination. They should be easy to clean and resistant to oils, chemicals, and high temperatures.

2. Mining and Quarrying: The mining and quarrying industry requires conveyor belts that can withstand heavy loads, sharp edges, and abrasive materials. Belts made of durable materials like rubber or steel are commonly used in this industry to ensure high-performance and minimize downtime.

3. Automotive: The automotive industry often deals with high-speed production lines and heavy parts. Conveyor belts used in automotive manufacturing need to be robust, resistant to oil and grease, and capable of withstanding high temperatures. They should also provide accurate positioning and reliable transportation.

4. Packaging and Logistics: The packaging and logistics industry relies heavily on conveyor belts for efficient and fast transportation of goods. In this industry, belts with high load capacity, gentle grip, and low friction are preferred to prevent damage to delicate or fragile items. Flexibility and modularity are also essential to accommodate various packaging sizes and shapes.

By understanding the specific needs and challenges of your industry, you can make an informed decision when selecting the right conveyor belt type. This will ensure that your production line operates at its optimal efficiency, leading to increased productivity and reduced operational costs.

Impact of conveyor belt selection on efficiency and productivity

Selecting the right conveyor belt type can have a significant impact on the efficiency and productivity of your production line. Here are some of the key benefits that come with choosing the appropriate conveyor belt:

1. Reduced Downtime: A conveyor belt that is specifically designed for your industry’s needs will minimize downtime caused by maintenance or repairs. By choosing a belt that can withstand the specific demands of your production line, you can ensure uninterrupted operation and increased productivity.

2. Increased Lifespan: Conveyor belts that are not suitable for the materials or environmental conditions they operate in are prone to premature wear and tear. This can lead to frequent belt replacements, increasing costs and causing disruptions in production. By selecting a conveyor belt type that is designed to handle your specific requirements, you can extend the lifespan of the belt and reduce maintenance expenses.

3. Improved Efficiency: The right conveyor belt type can optimize the speed and capacity of your production line, resulting in improved efficiency. Whether it’s faster transportation of goods or increased throughput, an appropriate conveyor belt can help streamline your operations and maximize productivity.

4. Enhanced Safety: Conveyor belts that are not suitable for the materials or products being transported can pose safety risks. For instance, belts that are too slippery might cause items to slide or fall off, leading to accidents or damage. By choosing a conveyor belt type that provides the necessary grip and stability, you can ensure a safer working environment for your employees.

Common mistakes to avoid when selecting a conveyor belt type

While selecting the right conveyor belt type is crucial, there are common mistakes that should be avoided to ensure optimal performance and efficiency. Here are some of the common mistakes to watch out for:

1. Ignoring Material Compatibility: Failing to consider the compatibility of the conveyor belt with the materials being transported can lead to premature wear and tear. It is essential to choose a belt that is resistant to the specific characteristics of the materials, such as abrasion, temperature, or chemical exposure.

2. Overlooking Environmental Conditions: Environmental factors such as temperature, humidity, or exposure to chemicals can have a significant impact on the performance and lifespan of the conveyor belt. Ignoring these factors can result in belt degradation and increased maintenance costs. It is crucial to choose a belt that can withstand the specific environmental conditions of your facility.

3. Underestimating Speed and Capacity Requirements: Choosing a conveyor belt with inadequate speed or load capacity can lead to bottlenecks and reduced productivity. On the other hand, selecting a belt that is too fast or has a high load capacity might put excessive strain on the system. It is essential to accurately assess the speed and capacity requirements of your production line to ensure optimal performance.

4. Not Considering Future Growth: Failure to consider future growth and scalability can result in the need for frequent belt replacements as your production demands increase. It is important to choose a conveyor belt type that can accommodate future expansion and prevent unnecessary downtime or additional costs.

Avoiding these common mistakes and thoroughly evaluating your specific needs will help you make an informed decision when selecting a conveyor belt type. This will ensure that your production line operates at its maximum efficiency, leading to increased productivity and reduced operational costs.

Maintenance and care for conveyor belts

Proper maintenance and care are essential for optimizing the performance and lifespan of conveyor belts. Regular maintenance not only extends the life of the belt but also minimizes downtime and reduces the risk of breakdowns or accidents. Here are some maintenance tips to keep in mind:

1. Regular Inspections: Regularly inspect the conveyor belt for signs of wear, damage, or misalignment. Look for any fraying, cracking, or tearing of the belt and address any issues immediately. Ensure that the belt is properly aligned and tensioned to prevent excessive wear and premature failure.

2. Cleaning and Lubrication: Clean the conveyor belt regularly to remove any debris, dirt, or contaminants that can cause damage. Use appropriate cleaning methods and products that are compatible with the belt material. Additionally, lubricate the belt and other moving parts as recommended by the manufacturer to minimize friction and reduce wear.

3. Training and Education: Properly train your employees on the correct operation, maintenance, and safety procedures related to conveyor belts. This will help prevent accidents, minimize damage, and ensure that the belts are used correctly and efficiently.

4. Scheduled Maintenance: Implement a scheduled maintenance program to address any potential issues before they escalate. This includes regular inspections, belt replacements when necessary, and addressing any maintenance or repair needs promptly.

By following these maintenance and care tips, you can maximize the lifespan of your conveyor belts and ensure optimal performance. Regular maintenance not only reduces the risk of breakdowns and accidents but also helps maintain the efficiency and productivity of your production line.

Finding the right supplier for conveyor belts

Selecting the right supplier for your conveyor belts is just as important as choosing the right type. A reliable supplier will provide high-quality belts that meet your specific requirements and provide excellent customer support. Here are some factors to consider when choosing a supplier:

1. Expertise and Experience: Look for a supplier with extensive expertise and experience in conveyor belt manufacturing and distribution. They should be knowledgeable about different industries and understand the specific needs and challenges of your industry.

2. Product Quality and Range: Ensure that the supplier offers high-quality conveyor belts that meet industry standards and regulations. They should provide a wide range of options to choose from, catering to different applications and requirements.

3. Customization and Flexibility: A good supplier should be able to offer customization options to meet your specific needs. They should be flexible in terms of belt dimensions, materials, and other specifications.

4. Support and Service: Look for a supplier that provides excellent customer support and after-sales service. They should be responsive to your inquiries, provide technical assistance when needed, and offer prompt delivery of replacement belts or spare parts.

5. Reputation and Reviews: Research the reputation of the supplier by reading customer reviews and testimonials. Look for a supplier with positive feedback and a good track record in terms of product quality and customer satisfaction.

Choosing the right supplier is crucial to ensure that you receive high-quality conveyor belts that meet your specific needs. A reliable supplier will not only provide the right type of belt but also offer ongoing support and assistance to optimize the performance and efficiency of your production line.

Conclusion

The importance of selecting the right conveyor belt type for efficiency cannot be overstated. A well-chosen conveyor belt can optimize the performance of your production line, minimize downtime, and maximize productivity. By considering factors such as material compatibility, environmental conditions, speed and capacity requirements, and industry-specific needs, you can make an informed decision when choosing the right conveyor belt type.Avoid common mistakes such as ignoring material compatibility, overlooking environmental conditions, underestimating speed and capacity requirements, and failing to consider future growth. Implement regular maintenance and care practices to maximize the lifespan and performance of your conveyor belts. Finally, choose a reliable supplier that offers high-quality belts and excellent customer support.With the right conveyor belt type, you can ensure a smooth and efficient operation, reduce maintenance costs, and increase productivity. Don’t overlook the importance of this crucial component in your production line. Choose wisely and reap the benefits of improved efficiency and productivity.